Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

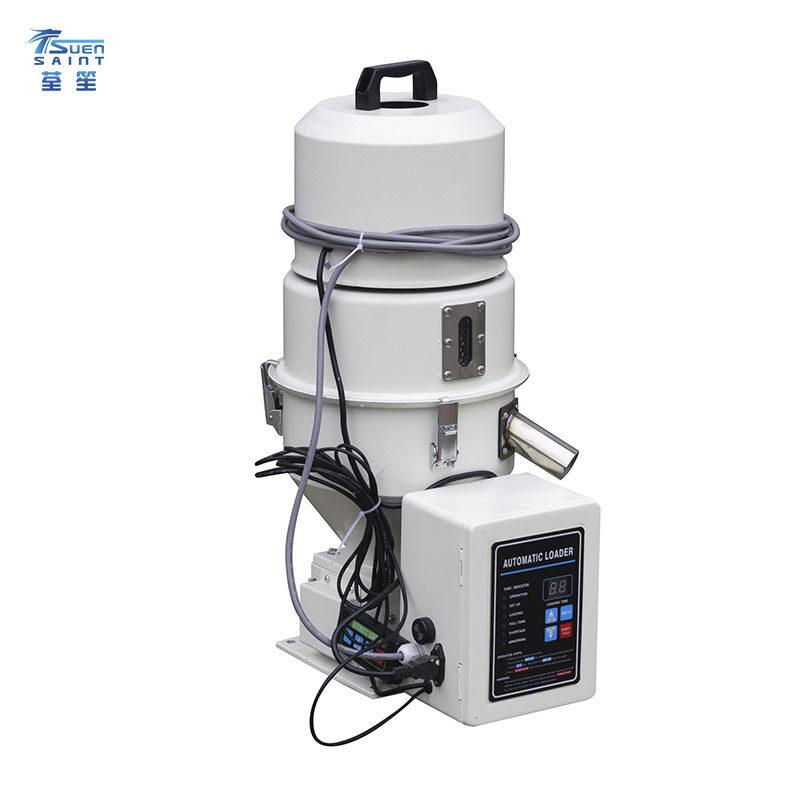

Plastic Raw Material Drying Oven Baking Machine Plastic Granule Hopper Dryer For Injection Molding

The plastic raw material drying oven baking machine, a cutting-edge solution for drying plastic granules in Injection Molding. This advanced equipment ensures optimal drying conditions, eliminating moisture and impurities. With precise temperature and airflow control, it enhances efficiency and reduces defects in the final products. User-friendly controls and durable construction make it a reliable choice.

Plastic Drying Oven Baking Machine

Product Description

Our plastic raw material drying oven baking machine, exemplifies precision engineering, purpose-built for drying plastic granules ahead of injection molding. Meticulously designed with a strong emphasis on performance and reliability, it creates a controlled environment to eliminate moisture, elevating the overall quality of the injection molding process. This machine ensures optimal conditions, enhancing mold longevity, reducing defects, and delivering superior results in the production of high-quality injection-molded products.

Product Features

Precision Drying: The oven ensures precise and thorough drying of plastic raw materials, preventing moisture-related defects in injection-molded products.

User-Friendly Controls: Equipped with intuitive controls for easy operation, allowing users to customize drying parameters for different types of plastic materials.

Space-Efficient Design: Compact and space-saving design without compromising on drying capacity, making it suitable for various manufacturing setups.

Energy-Efficient Operation: Incorporates energy-efficient mechanisms to optimize the drying process while minimizing energy consumption, contributing to cost savings.

Product Advantages

Improved Injection Molding Quality: By efficiently removing moisture, this machine plays a pivotal role in enhancing injection molding quality. It mitigates defects, ensuring the production of flawless molded products. The meticulous moisture control contributes to a consistently high standard, meeting stringent quality requirements and boosting overall production outcomes.

Versatile Material Compatibility: Tailored to accommodate diverse plastic granules, this machine offers unparalleled flexibility for various injection molding applications. Its versatility allows manufacturers to seamlessly adapt to different material requirements, promoting efficiency and adaptability in the production process.

Time and Cost Savings: With precision drying capabilities and energy-efficient operation, this machine translates to tangible time and cost savings. Reduced cycle times optimize production efficiency, while energy efficiency contributes to lower operational costs. This dual benefit positions it as a cost-effective solution, aligning with manufacturers' financial objectives.

Enhanced Equipment Longevity: Beyond elevating product quality, the controlled drying environment extends the lifespan of injection molding equipment. This ensures sustained and reliable performance, minimizing downtime and maintenance costs. The machine's impact goes beyond immediate production, promoting long-term operational efficiency and equipment durability.